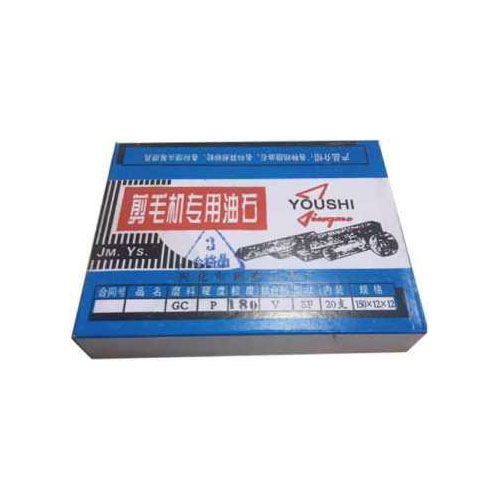

Grindstone for Shearing Machine

As a supplier dedicated to textile machinery, Ceres Machinery has been constantly exploring and innovating, hoping to provide more and better solutions for our customers. The grindstone for shearing machine is specially developed for shearing machine industry, which has excellent performance and wide application fields. It uses high-quality materials and advanced production technology to ensure its stable quality and good use effect.

Send Inquiry

Ceres Machinery is a professional manufacturer, which is committed to producing high-quality grindstone for shearing machine. They adopt advanced production technology and exquisite craftsmanship to ensure that each product can meet the highest quality standards. The products of Ceres Machinery have a longer service life and better performance, so we strongly recommend that you choose Ceres Machinery's grindstone for shearing machine to ensure that your shearing machine is always in the best condition.

Oilstone is a large consolidated abrasive made of abrasive and binder. Oilstones are usually lubricated when used. Oilstones are generally used for hand grinding tools and parts, and can also be clamped on machine tools for honing and ultra-precision machining. There are two types of oilstones: artificial and natural. Artificial oilstones have two structural types because of the different abrasives used. ① Matrix-free oilstones made of corundum or silicon carbide abrasive and binder can be divided into square, rectangular, triangular, knife-shaped (wedge-shaped), round and semicircular oilstones according to their cross-sectional shapes; (2) matrix oilstones made of diamond or cubic boron nitride abrasive and binder, including rectangular, triangular and arc oilstones. Natural oilstone is made of natural quartzite with fine texture and grinding and polishing ability, which is suitable for manual precision grinding in manufacturing industries such as precision machinery, watches and tools.

Advantages of oilstones in knife sharpening

1. High Efficiency: Sharpening knives with an oil stone can greatly increase the efficiency of sharpening. This is because it has high hardness and sharpness, and can quickly grind the surface of the tool in a short time without generating too much heat, avoiding excessive wear of the tool.

2. Long life: Compared with traditional sharpening strips, the oil stone has a much longer life. According to statistics, it lasts about 500 times longer than traditional abrasives. This means that using an oil stone can greatly reduce the number of times you need to replace abrasives, increase productivity and save money at the same time.

3. High precision: Another significant advantage of the oil stone is that it can provide high precision grinding. Due to its own fine material, the depth and precision of grinding can be well controlled, so that the surface of the tool is smoother and flatter.

4. Easy to operate: The oil stone itself is relatively durable and not easy to break, so it can maintain its shape and size stability during use, making the grinding process more stable and controllable.

5. Multifunctionality: oil stone can be used not only for grinding tools, but also for grinding, polishing and other processing operations, which is highly practical.

Please feel free to contact us if you have any questions or cooperation intentions about the oilstone special for grindstone for shearing machine or other products. We will wholeheartedly provide you with comprehensive technical support and after-sales service to ensure that you can give full play to the advantages of products and meet your needs.